Hydraulic Cylinders

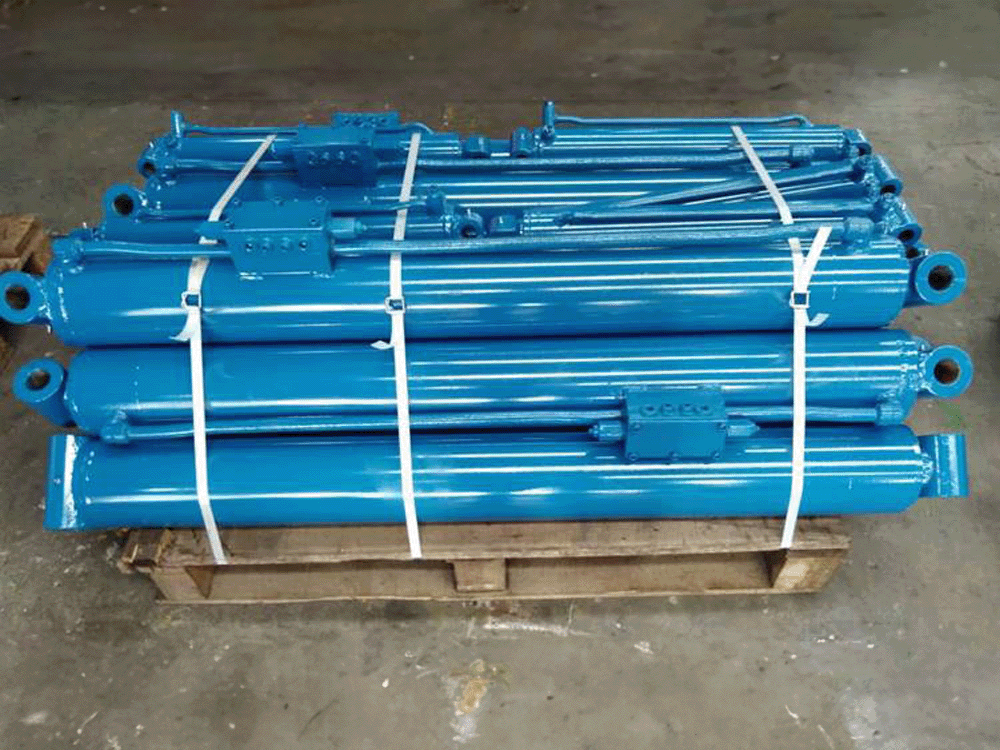

Since 1977, Powermatics had led the industry as a trusted manufacturer of high-quality hydraulic cylinders for the OEM market, engineered to perform in harsh environments like offshore, construction, heavy industry and waste management

Product Overview

Hydraulic cylinders can be engineered for a wide range of applications, offering innovative designs tailored to unique operational needs. Known for their durability, power efficiency, and load-handling capability, hydraulic cylinders are often the superior choice in industrial scenarios. They provide precise control, versatility, and reliable performance with low maintenance requirements.

Our technical team work closely with clients to design and manufacture cylinders that meet precise specifications, ensuring exceptional performance and durability.

Types of Hydraulic Cylinders

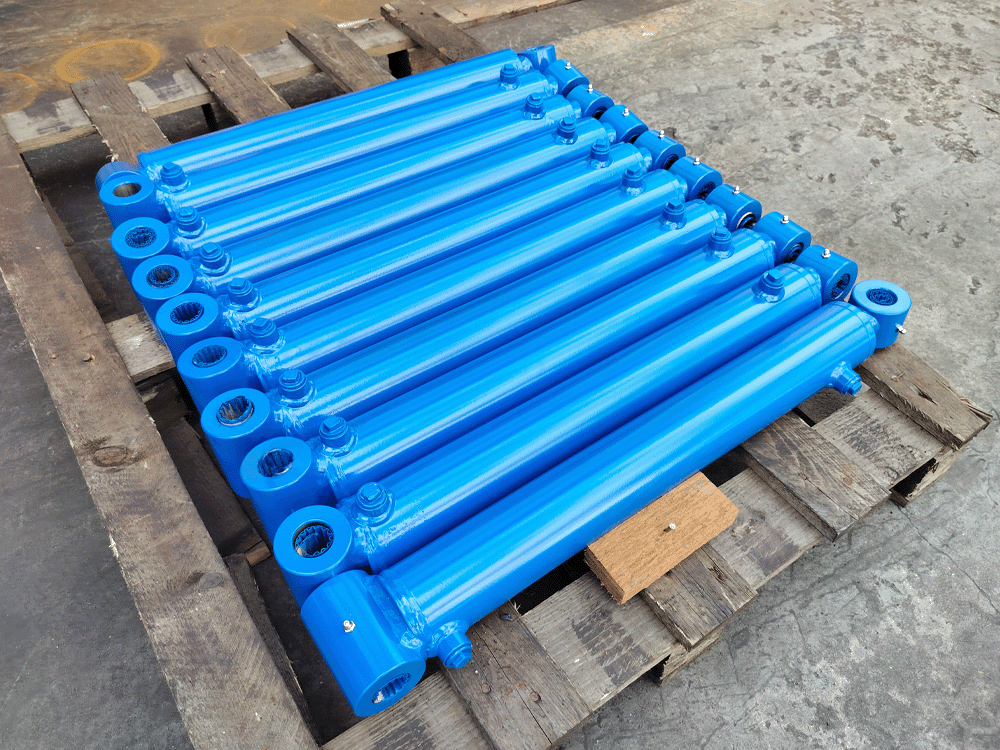

PHE hydraulic cylinders are available in several types, each designed for different functions:

- Single Acting and Displacement Cylinder: Actuated by pressure on one side; returns to initial position by external forces.

- Spring Return Single Acting Cylinder: Commonly used for locking, clamping, braking, and load holding applications.

- Double Acting Cylinder: Capable of both pushing and pulling applications, most widely used across various industries.

- Telescopic Cylinder (Multiple Stages): Suitable for single or double acting applications. These cylinders offer long strokes with a compact cylinder length, albeit with a more complex and typically higher cost construction.

Types of Hydraulic Cylinders

Our hydraulic cylinders can be integrated with a range of advanced features to enhance their functionality:

- Valves: Including PO check valves, counterbalance valves, cushioning feature, and more.

- Sensors: Position sensors such as inductive sensor, linear displacement transducer and other monitoring capabilities.

- Other Custom Designs: Such as double rods, tandem design, piggyback setup, booster cylinder, hydraulic rotary, and beyond.

Technical Features

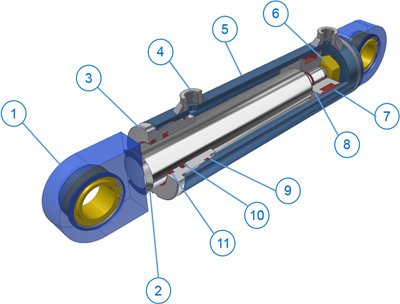

1. Rod End Clevis – Rod end mounting style available to suit all application

2. Piston Rod – Standard C45/C50. Medium carbon steel, hard chromium plated at least 20 µm thickness. 3. Surface finish, Ra ≤ 0.2 µm (8Rms);Diameter tolerance ISO f7. Yield stress is 340 to 517 N/mm2. Other piston-rod materials and surface treatment are available.

3. Heavy Duty Head Gland – Machined from ductile iron for maximum bearing support and wear resistance.

4. Connection Port – With standard threads.

5. Cylinder Barrel – Heavy wall steel tubing honed or skived and roller burnished to assure minimum seal friction and wear.

ø40mm-ø200mm:Skived and roller-burnished steel tube (to a surface finish of Ra ≤ 0.2 µm). Stress relief annealed after the last cold drawn process. Minimum yield stress is 520 N/mm2

ø200mm:Honed steel tube to a surface finish of Ra ≤ 0.4 µm. Minimum yield stress is 355N/mm2.

6. Lock Nut – Self-locking piston nut.

7. Piston Seal – High pressure piston seal with wear ring provides leak proof operation.

8. Piston – Designed to assure leak proof and reduced bearing load. Material: ductile iron or steel

9. Head Gland Seal – O-ring with back-up-ring provides positive sealing between gland and barrel.

10. Rod Seal – Long life urethane rod seal prevent hydraulic oil leakage.

11. Rod wiper – Double-lip rod wiper provides dirt protection and wipes rod clean on in-stroke.